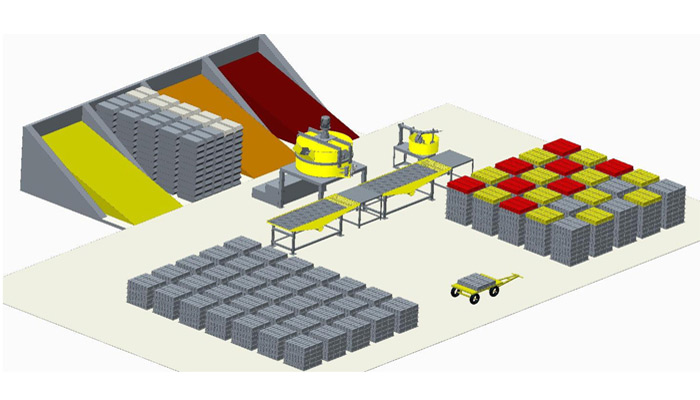

Automatic Rubber Mould Paver Block Plant

Rubber Mould Paver Block Plant

Paver blocks date back to the Roman Empire, where interlocking stones were used to build roads. Modern paver blocks were developed in the mid-20th century in Europe, with significant advancements in the materials and manufacturing processes. The introduction of Rubber Moulds has further revolutionized the industry by improving design versatility and surface finish.

The primary purpose of manufacturing paver blocks is to provide a durable, versatile, and eco-friendly solution for outdoor flooring. Paver blocks are preferred over traditional concrete slabs due to their ease of installation, cost-effectiveness, and the ability to withstand heavy loads and adverse weather conditions.

The quality and strength of paver blocks depend on the raw materials used. Key raw materials include:

Grades and Thickness of Paver Blocks

Paver blocks are available in different grades and thicknesses, depending on the application:

Grades

Thickness

Global Paver Block Market: The global paver block market is growing at a CAGR of around 5.7%, driven by the increasing focus on sustainable and durable construction solutions.

Load-Bearing Capacity: High-grade paver blocks (M40 and above) can withstand loads of up to 40 MPa, making them suitable for roads with heavy traffic.

India Market Insights: In India, the paver block industry is booming, with annual production exceeding 10 million square meters due to urbanization and infrastructure development projects.

Scope of Balaji |

||

| Required Machines for plant | Qty | Kw |

| Vibrating Table | 2 | 1.49 |

| Plain table | 2 | 0.00 |

| Pan type Concrete Mixer 3.0 | 1 | 3.73 |

| Manual liquid Mixer | 1 | 2.24 |

| Mold transport cart | 2 | 0.00 |

| Total | 7.46 | |

Scope of Customer |

|

| Plant Civil work requirments | Value |

| Shed for Machines (L x W x H) (feet) | 40 x 15 x 16 |

| Coverd area for 1st day curing | 1000 Sqft |

| Raw material storage space | 1200 Sqft |

| Finished goods storage space | 1500 Sqft |

| Labour hatment space | 500 Sqft |

| Office and other | 200 Sqft |

| Total | 5000 Sqft |

| Wodden pallets 900 x 900 x 16 mm | 200 |

| Rubber / PVC / plastic molds | 2500 |

Production Requirments |

|

| Required labours for plant | Numbers |

| Raw material for Colour mixer | 1 |

| Colour layer feeding | 1 |

| Raw material for Concrete mixer | 2 |

| Concrete layer feeding | 2 |

| Unloading from vibrator table | 2 |

| Demolding | 2 |

| Total | 10 |

| vehical loading unloading extra | 2 |